Widespread experience in manufacturing and designing HVAC equipment resulted in range of products created to successfully address various air conditioning, ventilation and air distribution problems. Termovent Air Handling Units can cover various air flow rates ranging from 800 to 100,000 m3/h. The Air Handling Units can be produced in more than 30 standardized sizes, with high levels of customization to satisfy customer requirements and project specifics.

By TERMOVENT

Std | Pro

- Standard type of TERMOVENT wide-area air handling unit – for catering facilities, cafes, restaurants, hotels, shopping malls and public facilities to industrial plants, warehouses and production halls.

- The modular design of this unit provides a wide range of applications by combining various functional units (modules) for: ventilation, heating, cooling, filtration, humidification, air dehumidification, recuperation and energy regeneration.

- Construction is a combination of aluminum profiles and plastic laminated panels, filled with polyurethane or rock wool.

- Thermally separated modular design

- Exterior or interior installation

Hydra | Pro

- Designed for the air conditioning of all types of indoor swimming pools – from private to Olympic ones.

- The autonomous solution regulates the microclimate conditions in the pool area with maximum utilization of waste airborne energy, which can also be used for pool water heating.

- The emphasis is on great energy-saving and economical operation during the exploitation of the device.

- Both models have a double plate recuperator.

- Plug and Play device.

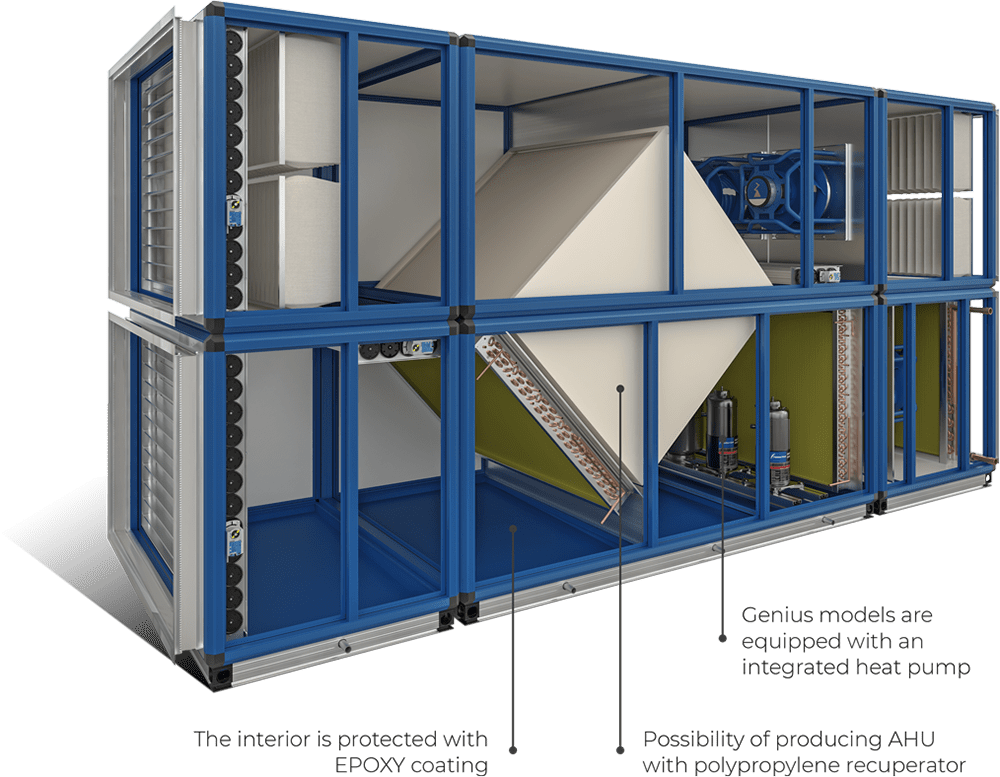

- The interior of the unit is protected with EPOXY coating.

- Possibility of producing a unit with polypropylene recuperators

Hygiene | Pro

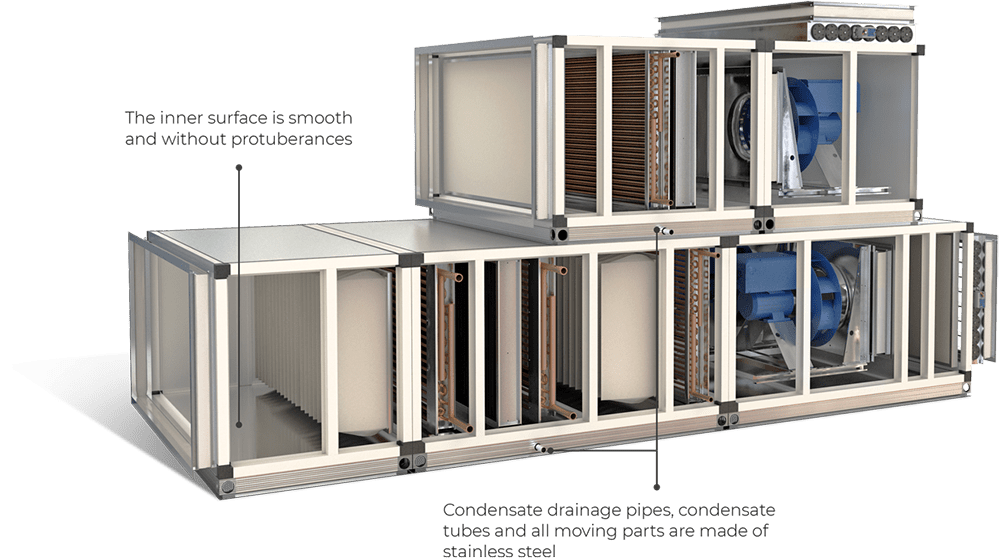

- special performance of modular devices that are applied in special, demanding projects, where it is necessary to provide an appropriate class of air purity in accordance with GMP, FDA, HACCAP norms.

- Application – operating rooms, laboratories, pharmaceutical production facilities, food, military or electronics industries…

- Prevention of space contamination

- All elements are easily approachable for washing and disinfection

- Formation of undesirable microorganisms is prevented

Energy | Pro

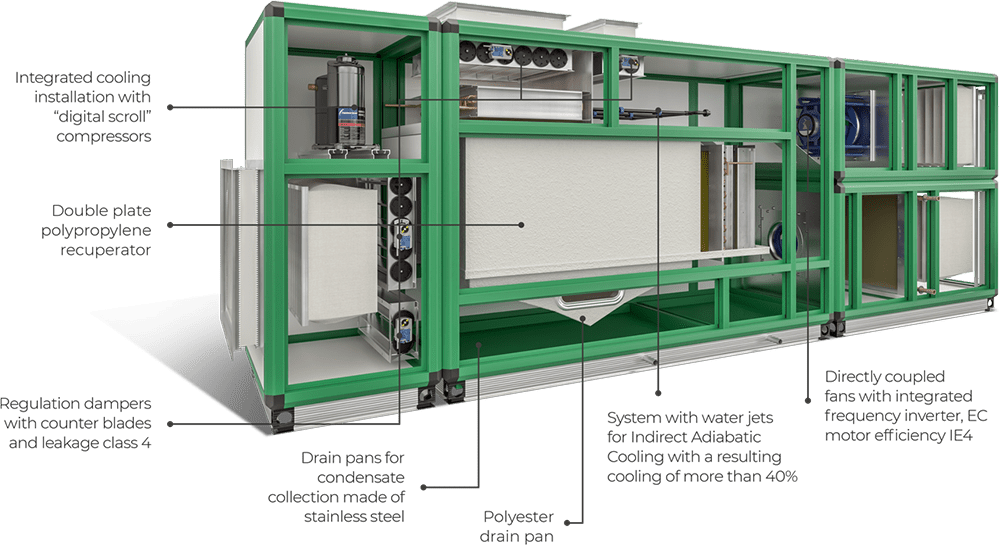

- air handling units include two groups of air handling units: energy | pro, and energy | pro-Adiabatic.

- Sensitive heat exchange between the waste air stream and the fresh air stream is carried out by using a two-stage double plate heat exchanger (the heat recovery rate reaches 80%).

- Completely autonomously maintain optimum microclimate conditions.

- Prevented the occurrence of condensate in a stream of supply air

- Prevented water leakage into the exchange section

- An ecological system with low power consumption and low CO2 emissions

- The optional ENERGY:pro design without integrated cooling installations with compressors